Account

All forum posts

Tyre Woes - Opinions on best way forward

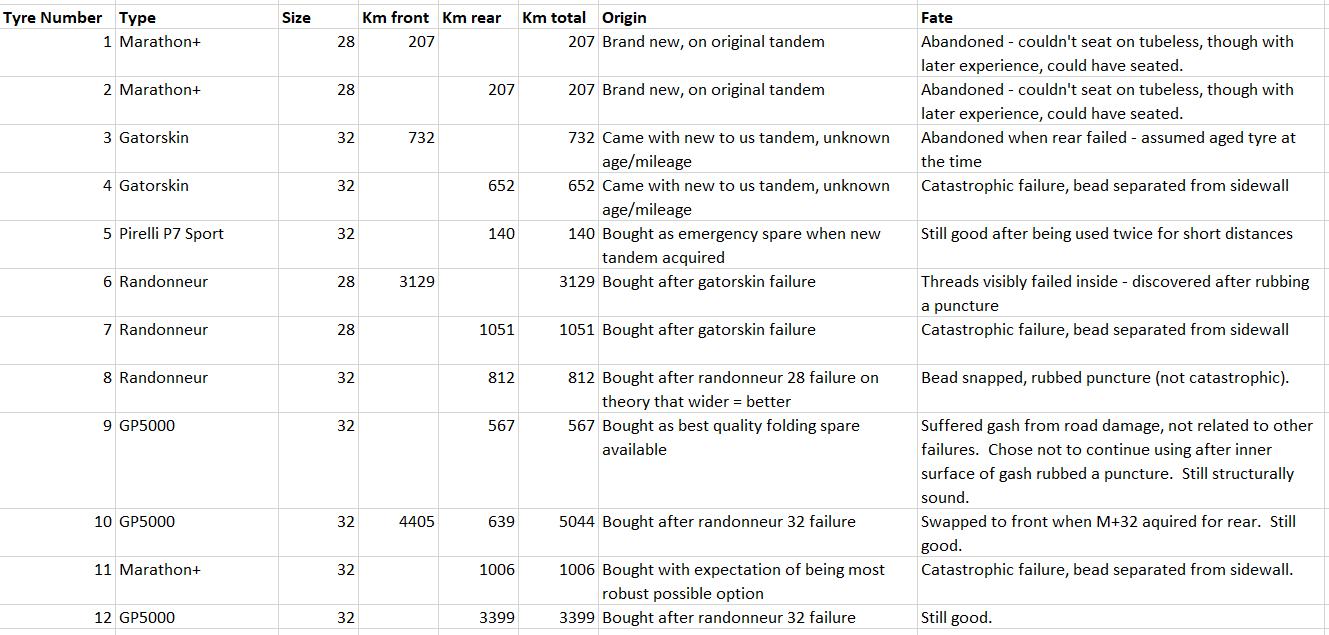

We are just back from a long tour of Europe (~8500km). Just three days in, we had to acquire a "new to us" tandem after a frame failure. The new machine has performed impeccably save for one serious issue - repeated catastrophic rear tyre failures with the sidewalls tearing just above the bead.

The rims are "tubeless ready" Ambrosio P20 36H, 700C.

A summary of all the tyres used is attached; all were run at ~10% above nominal pressure rating, from 85-110psi depending on the tyre.

Eventually we found that GP5000 tyres were robust and completed the trip with those, covering several thousand kms without mishap.

Our all up weight is about 200kgs, and there is no clearance for larger tyres than 32mm. We had previously run 28mm tyres for many years on our old 48 spoke rims without any problems, most recently with marathon plus tyres.

I would appreciate experience of similar issues and how they were resolved. My best guess is that the tubeless ready tyres impose too tight a radius on the tyre for our weight where they hold it in - there is a very loud "snap" as they seat, and they're held very tight. but perhaps there are other possible issues.

The previous owners didn't have these issues, and Pete Bird at the tandem shop who build the bike and wheels was also very surprised to hear what was happening.

Whilst the current tyres seem OK, I'm not confident that they will remain so, and don't in any case want to be restricted to a single tyre choice. So we need to decide whether to get the wheels re-rimmed (and if so with what), or whether a different tandem with wider tyres is in fact what we need for touring.

All opinions and advice very welcome; I'll follow up with a few pictures.

Thanks - unfortunately we don't have a spare, but also testing a different rim would be quite difficult; these failures all happened after 500+ miles fully loaded so I guess you'd want at least 1000 miles to be confident in a different rim which isn't a trivial testing exercise!

Forgive me for suggesting something so simple and I'm sure you have checked this already but it's not a rim brake pad issue is it ? The rims look like they're used for braking and my only experience of this kind of failure is down to worn pads contacting the tyre.

great tour btw.

Thanks for the suggestions, appreciated.

I should have said - they're disc brakes. There is a parking rim brake as well, but it's definitely not that.

As far as I can, I've checked the rim very carefully for any sharp/ abrasive issues and can't find any. The last two failures were at different points on the rim, which suggests it's more general I think?

Could be just heat, causing the pressure rise beyond the safe one, and a failure at a weaker point?

Could be just heat, causing the pressure rise beyond the safe one, and a failure at a weaker point?

There's no source of heat at the rim - disc brakes

Some of these failures were in cold ambient conditions.

Why have you gone +10% on max rated pressures? The roads can be at over 50°C which will increase pressures further.

The only thing left to change is the rim.

On temperatures, the first two failures were in single digit (centigrade) and the tyres had never seen ambient temperatures beyond mid teens at most. Later, temperatures were much higher.

So I think temperature can be ruled out.

On pressure, opinions vary widely! Some people (and guidance, eg Sheldon) advise pressures even higher, given tyre size and load. Others think lower pressures better. 10% over was advice from tandem shop, who built both bike and wheel, and made sense to me, so we did that and were really careful to keep it consistent. But I'm open minded on this for the future.

It does appear that the rim is the only constant. P20's are known for being tight for tyre fitting, are you confident of no slight damage during fitting that has then been exasperated by loaded Tandem use, the photo does not show signs of any abrasion near the sidewall split. Also check what width of rim tape you are using, it should be no wider than the rec. Tubeless tape for that rim. This can cause issues with space for tube/tape/sidewall. Do the GP5000's go on easier? is that a pointer that other tyres are getting stressed when fitting. I use H+Plus Son rims and can roll them on by hand and only light tyre lever use to get them off. I would not run them higher than marked, they are already under much more stress on a Tandem than a solo. Wider tyres give a better ride, handle the weight better, need less air due to volume, and roll surprisingly fast, albeit a bit heavier so slower on hills and acceleration.

And without going into detail, there are better places to go for advice than where you mention.

Thank you Kevin.

Damage on fitting is an interesting suggestion and I guess could be possible, though I think unlikely. I don't remember the earlier ones, but the M+ required straps to keep them in the well opposite the valve and a VAR lever to mount. GP5000s can be mounted purely by hand without levers. The M+ that failed was never removed before failure, and I only used plastic levers for removal of any of them, so about as low impact as it's possible to be, I think.

I didn't see any sign of abrasion on any of the tyres, just a catastrophic split. But equally I wouldn't really know what to look for.

32s are the widest tyres we have clearance for (we did try a 35 and no-go)

Would appreciate your recommendations on where to go for professional advice.

Having read all this correspondence with great interest, and with a working lifetime of mechanical engineering/reliability behind me, I would like to make a few observations.

the first is, these look like stress/fatigue failures to me, and specifically, stress in the tyre sidewall. So I've had a look at manufacturers data for load rating. Schwalbe helpfully provide load ratings on their website:- and clearly, they do not make a 32mm wide tyre with a load rating of over 90kg! If your all up weight is 200kg as you state, then the load on the rear tyre will typically be 130kg (I.e. something like 2/3 of the total), and transiently, it will be higher than that. So premature failures are to be expected. I can't find the equivalent data for GP5000 tyres, these are excellent tyres and perhaps have a higher rating, but I suspect that you are still running them in overload to some extent.

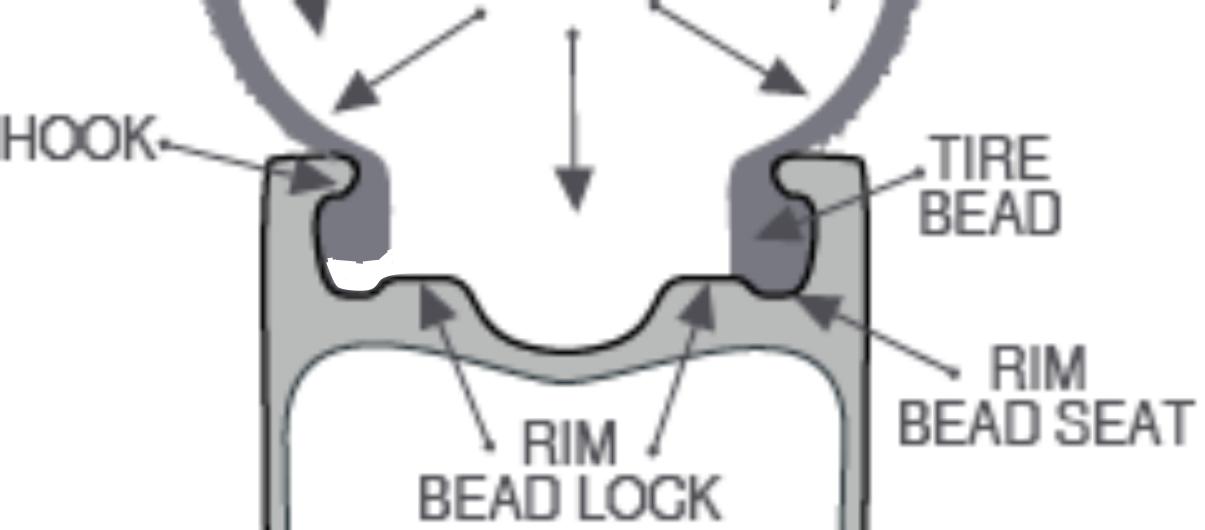

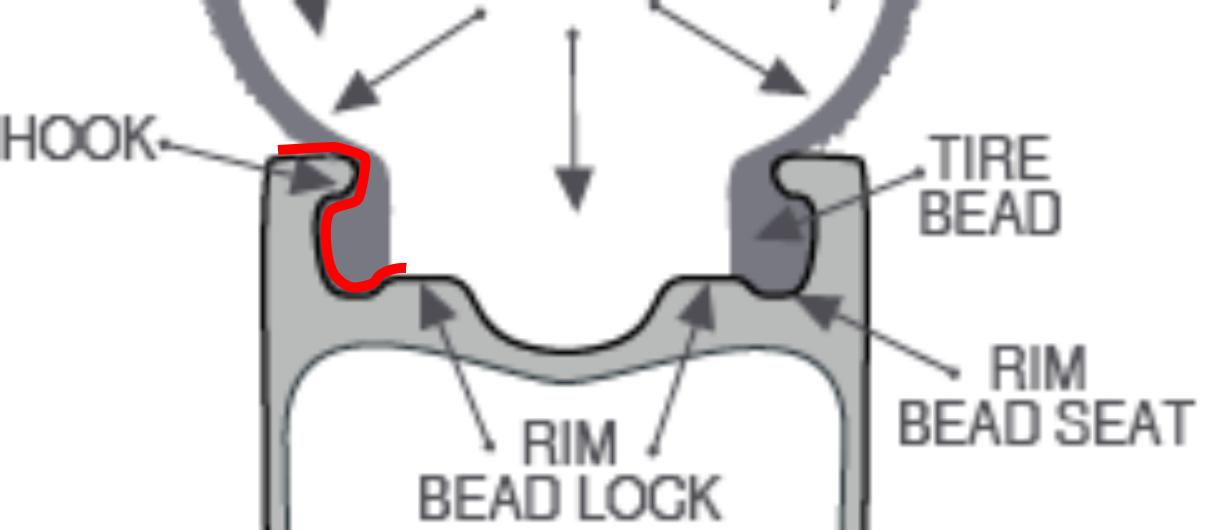

As for all the discussion about whether it's the rim profile causing the problem, or the 'tubeless ready' rims:- I think you can forget all that. The profile of the wall is a standardised 'hooked' profile for all manufacturers, and once seated, there is no difference between tubeless ready and 'normal' designs.

So I think you have a straight choice:- either accept that you only have one source of reliable tyres, OR, change your frame for one which will accommodate larger tyres with a higher load rating. And you have done a pretty good job of testing the GP 5000's!

Finally, congratulations on a brilliant tour:- quite envious.......

Nicholas, thank you very much for taking the time, your expertise and experience both appreciated, and I can't fault your logic. However...

There is definitely something different about these rims- seating tyres is extremely difficult (tyres would not seat at even 120 psi until we started lubricating them) and when they do finally seat they make a very loud "snap". Whether or not that's related to the failures, I don't know. Lubricated, tyres typically seat at ~80 psi.

We've previously done many thousands of miles on even narrower tyres (28mm) on our old tandem on 48 spoke rims without any issue whatever. That included a 1000km tour last year with exactly the same load. Tyres most recently marathon plus, but probably various others over the years. Again, this suggests to me there's something rim specific here.

Of course, we may just have been very lucky for a very long time, or maybe tyres are specced less conservatively these days than they used to be.

Hello, we had exactly the same problem with tyres being damaged at the rim on our tandem. The first time it happened we’d only been touring for about four days I think, it’s so long ago. On the first occasion it was the back tyre that tore at the rim and we had a blowout. A few days later the front tyre went. So that was two new tyres I had to spend money on in the space of a couple of weeks. I had progressed my cycle craft to blowing up a tyre but after that clueless. I was though, parsimonious to a fault. I, therefore, borrowed some electrical black tape, put this round the inside of the rims with a little bit curving round the top edge of the rim but not on to the rim’s breaking surface. A ridiculously simple and cost-effective solution but we didn’t have another problem in all the years we had that tandem. You might be sceptical, I certainly was, and I was certainly in disbelief when it worked. So much so, that I took the tape off the front rim. About a week after, the side wall burst. I put the electrical black tape back on the rim and never tampered with it again. This might be too Heath Robinson a solution for you but you could try it until you find a technical solution.

Very interesting Michael! And glad to hear we're not alone at least.

Hi, Brian, I've been thinking about the good points you make in your response. Maybe all tandem tyres are tending to operate in overload, however the design margins built in by the manufacturers allow them to cope:- except in the case of your rear tyre! I've been thinking about the point you make re the tightness of the tyre on the tubeless-ready rim. It shouldn't take 120psi to get the tyre into the seating position. Thinking a little more around all this, I've come up with a new theory which I think fits the facts........

clincher tyres should be located by the bead of the tyre fitting into a matching groove in the wheel rim, where the pressure in the tyre causes them to be held firmly, primarily located on the outer shoulder of the bead. Therefore there should be no chafing or movement between the tyre and the rim as the wheel goes round. In your case, it sounds very much as if the tyre is locating primarily on the inside diameter of the bead/tyre, and under the very heavy loading of your rear wheel, the outside of the bead isn't held firmly enough to prevent chafing and movement, and under these conditions, it doesn't last very long.

The question then is, why are the GP5000's so much better. I have a theory......... GP5000's are a high performance folding tyre, with a fibre bead. As far as I've been able to make out, all the other tyres are wire beaded, I.e. have a steel wire moulded into the rubber to form the bead. This is significant for two reasons:- firstly, the steel wire is relatively in elastic, and will remain firmly located on the inner diameter of the tyre as you blow it up to full pressure, whereas the fibre bead will stretch, allowing the tyre to located properly on the outer diameter of the groove (and this really is a significant effect:- I use GP5000's on my road bike, and have used other folding tyres before, and you can see the stretch as you get up to full pressure:- and the tyres get noticeably bigger through their life, becoming easier to remove and replace!). The second reading is that if there is any relative movement, the steel wire will tend to cut through the relatively soft rubber and sidewall reinforcement.

SO, I can see two possible solutions:- replace your rims with 'ordinary' clincher rims, not tubeless ready (and I can't imagine you would want to run tubeless tyres on a tandem), or, much less drastically, explore other types of folding tyre. These are more expensive than beaded tyres, but would probably cost less than changing your rims, even in the long run! I see that the Schwalbe Marathon supreme is a folding tyre............

Nick Wells

What an interesting discussion and what a great forum of experts. I'd like to contribute my humble attempt of an explanation. This would have to explain both why the problem occurrs and also why it does apparently not occur with insulation tape.

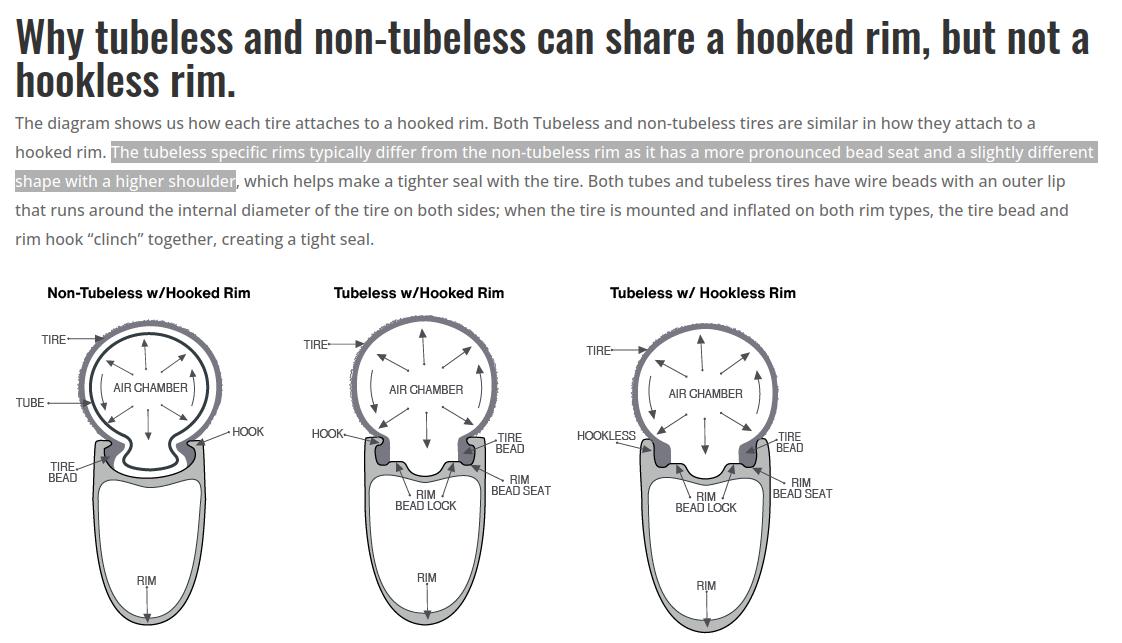

For the problem to occur there must be some movement between the hook of the rim and the tire material just above the bead. i.e. the bead must move up and down within the rim. And I thought it must be related to the "tubeless ready" feature of the rims. A little research led me to this page which explains that tubeless tires have a bigger cross section shape of the bead. http://www.neugentcycling.com/TubelessRimsExplained.html

So in a "tubeless ready" rim there would have to be more space in which a normal tires bead could move up and down. Another very helpful page for my speculation was this.

Thanks all for the continued inputs.

Steven,

tubeless tyres seem to come in lower pressure ratings (not sure why, I guess running lower pressure is par of the point of tubeless). More modern tubless rims seem to be hookless too, which must limit pressure rating, so there's no point testing higher than that?) So GP5000 tubeless 32mm is rated only at 73 PSI:

https://conti-tyres.co.uk/road-and-track/clinchers/grand-prix-5000s-tr

Whereas the standard one is 102 PSI:

https://www.conti-tyres.co.uk/road-and-track/clinchers/grand-prix-5000

For our duty, I think you'd want at least 100psi to take the weight?

I was completely unaware of all of this until trying to find tyres in Italy and to my surprise discovered the GP5000 on the shelf had a lower pressure rating than the one on the bike. One of the key advantages of folding tyres turns out to be that you can get them delivered to Amazon lockers (non- folding ones are too large) so we were able to get the higher pressure standard offering waiting for us a couple of days ahead.

Nick,

yes, perhaps it's the non-metal bead that makes the difference, and all folding tyres would be fine.

Dirk,

I wonder if the tubless design imposes a tighter bend radius at the hook and that's the nub of the issue - flexing that in situ causes the stress with no actuall movement or chafing necessary,.

Christopher,

the problem with testing is that these failures take ~1000km to manifest. So we'd need to do a 2000km loaded tour to test any solution!

Sounds the sensible way forward, a well proven tyre and rim combination.

I've got the G6000's with non-folding gatorskins on one of my tandems